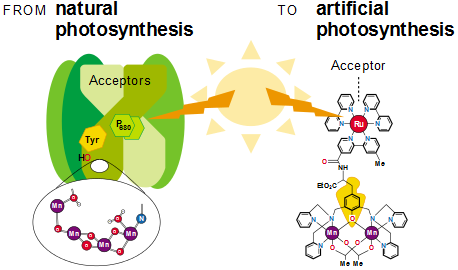

Algae are tiny

biological factories that use photosynthesis to transform carbon dioxide and

sunlight into energy so efficiently that they can double their weight several

times a day. Algae oil is an interesting sustainable feedstock for biodiesel

manufacturing. It is an alternative to popular feedstocks, like soybean, canola

and palm. In comparison to traditional oil-seed crops, algae yields much more

oil per acre. While soybean typically produces less than 50 gallon of oil per

acre and rapeseed generates less than 130 gallon per acre, algae can yield up

to 10,000 gallons per acre. In particular diatoms and green algae are good

sources for the production of biodiesel.

History as Fuel

The idea of using algae

as a source of food, feed and energy goes back more than half a century.

Production of methane gas from algae was proposed in the early 1950s, and

received a big impetus during the energy crisis of the 1970s, when projects

were initiated to produce gaseous fuels (hydrogen and methane). From 1980 to

1996 the US Department of Energy supported the Aquatic Species Program (ASP), a

relatively small effort (about $25 million over almost 20 years) with the

specific goal of producing oil from microalgae.

So exactly how can we get

oil from algae?

Algae are grown in either open-pond or

closed-pond systems. Once the algae are harvested, the lipids, or oils, are

extracted from the walls of the algae cells.There are a few different ways to

extract the oil from algae. The oil press is the simplest and most popular

method. It's similar to the concept of the olive press. It can extract up to 75

percent of the oil from the algae being pressed.

Basically a two-part

process, the hexane solvent method (combined with pressing the algae) extracts

up to 95 percent of oil from algae. First, the press squeezes out the oil.

Then, leftover algae is mixed with hexane, filtered and cleaned so there's no

chemical left in the oil.

The supercritical

fluids method extracts up to 100 percent of the oil from algae. Carbon dioxide

acts as the supercritical fluid . when a substance is pressurized and heated to

change its composition into a liquid as well as a gas. At this point, carbon

dioxide is mixed with the algae. When they're combined, the carbon dioxide

turns the algae completely into oil. The additional equipment and work make

this method a less popular option.

Once the oil's

extracted, it's refined using fatty acid chains in a process called

transesterification. Here, a catalyst such as sodium hydroxide is mixed in with

an alcohol such as methanol. This creates a biodiesel fuel combined with a

glycerol. The mixture is refined to remove the glycerol. The final product is

algae biodiesel fuel.The process of extracting oil from the algae is universal,

but companies producing algae biodiesel are using diverse methods to grow

enough algae to produce large amounts of oil.

Different Bio fuels

made with algae

Biodiesel - Microalgae

are involved in the production of biodiesel. Microalgae are chosen for the production of

biofuel based on their oil content. The oil inside the microalgae is removed from algae by

chemical means or either squeezed out. The oil is collected and changed chemically and

is then used as an ingredient in biodiesel.

Bioethanol – Bioethanol

is an ingredient used in the production of petrol. Macroalgae that contain a lot of

sugar are chosen. Macroalgae are cut, mashed and treated.The macroalgae now

appear as sludge and is called feedstock. Other micro-organisms

called Yeast are added at this stage. Yeast uses the feedstock

as food and breaks down

the feedstock into ethanol and other components. This process is called fermentation.

Ethanol is separated from the other components and then the ethanol is used in

petrol.

Biogas – Methane is the

main ingredient in the production of biogas. Methane gas can be produced by using

macroalgae. The macroalgae must have a high sugar content. Macroalgae are cut and

mashed. Micro-organisms convert the natural sugars in macroalgae into

glucose. The macroalgae now appear as sludge and is called feedstock. The feedstock will go

into a big tank and special micro-organisms called anaerobes are

added. These

micro-organisms are special because they don’t need oxygen to survive.They work without

oxygen(air). They also need an environment that has the correct temperature and

acidity. When conditions are correct the special micro-organisms perform a series of

reactions called anaerobic digestion.Within this environment

methane and other gases are produced. The methane gas is separated and used as

biogas.

Hartman, Eviana (6 January 2008). "A Promising Oil Alternative: Algae Energy". The Washington Post. Retrieved 1 May 2014.

http://en.wikipedia.org/wiki/Algae_fuel